Ru

|

Eng

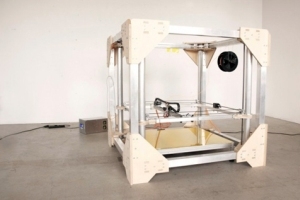

Rosatom plans to produce next generation 3D printer

24.03.2017

The Russian state-run nuclear industry corporation Rosatom plans to produce a next generation 3D printer for metal and composite products by the end of 2017, Aleksei Dub, first deputy director of Rosatom’s Science and Innovations Division, said at NDExpo 2017 in Moscow. He made a speech during the panel discussion on innovative technologies for the factories of the future. Aleksei Dub spoke about technologies and materials engineering solutions for digital manufacturing.

Rosatom has developed a prototype of a 3D printer Melt Master3D 550 that can manufacture figurine-shaped products from metal powder and alloys using selective laser melting method. The pilot product is being tested. The company has also carried out technical evaluation of the equipment used for different types of 3D printing. This equipment will operate on the basis of Russian topological optimization software for printing new design products.

“Industrial production of printers for three-dimensional printing of metal products has great prospects not only in the nuclear industry. Our country’s medical institutions need some 100,000 implants per year, and these implants can be manufactured using 3D printers. This market alone is estimated at more than RUB8 billion,” Aleksei Dub explained. “This is one of the ways to use 3D printed products. A next generation 3D printer able to print composite products as well as metallic ones will expand the scope of application of this technology”.

Additive technologies are a promising strategic line of business for Rosatom. The company expects the new printer to cost 20% less than its foreign analogues and be of higher quality. Metallic powders for 3D printing will also be produced in Russia. The main task today is to speed up the development of the legal framework for the use of this technology in mass production.

NEWSWIRE

17.07.2024

02.07.2024

27.06.2024

21.06.2024

19.06.2024

06.06.2024

06.06.2024

06.06.2024

06.06.2024

06.06.2024